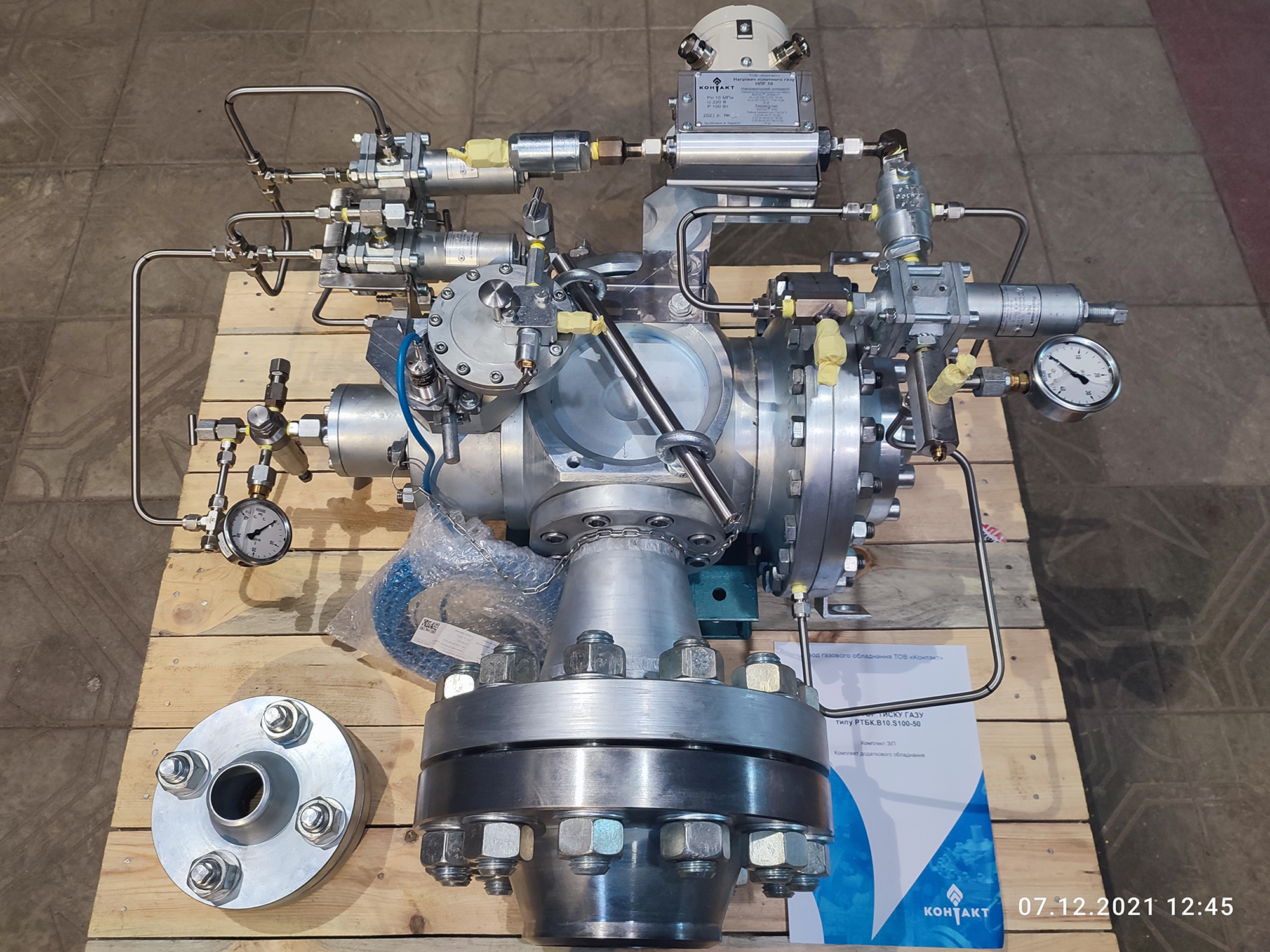

On December 07, 2021, the first two RTBK gas pressure regulators of block type were released for manufacturing!

These regulators are designed to meet the requirements of DSTU EN 334:2015 and have been certified for compliance with the requirements of modern technical regulations.

During the past one and a half years, the technical specialists of the Kontakt LLC plant went a long way from studying the needs of the gas transportation market to the delivery of the first batch of RTBK regulators to Ukrtransgaz JSC.

In the process of design development, the possibility to offer the Customer more than 12 modifications of the RTBC regulator was taken into account.

Based on standard parts, we can combine different versions of the regulator, such as:

In the process of design development, the possibility to offer the Customer more than 12 modifications of the RTBC regulator was taken into account.

Based on standard parts, we can combine different versions of the regulator, such as:

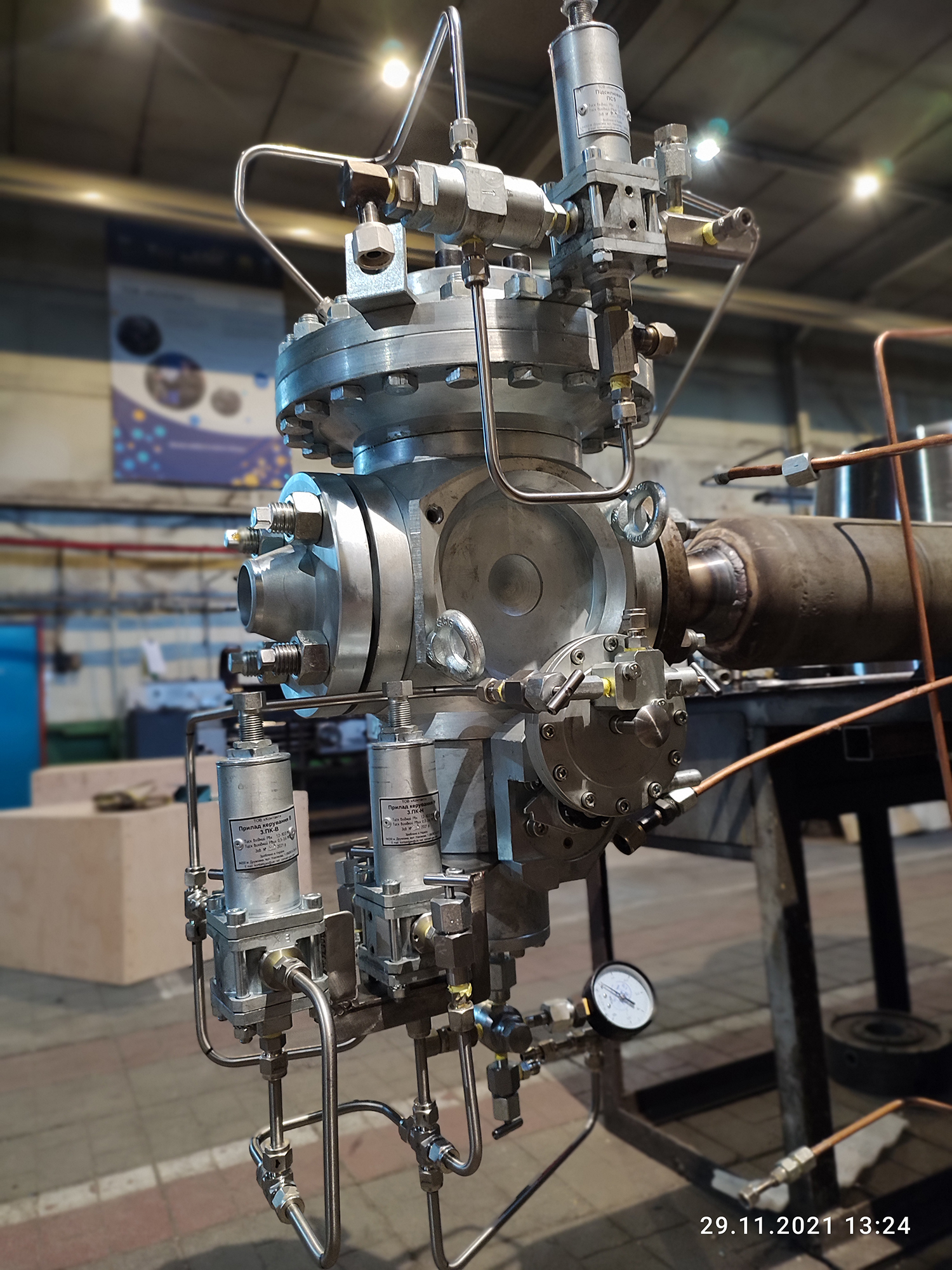

In the spring of 2021, a prototype of the RTBK regulator was manufactured and plant tests were carried out.

In September, the plant received Certificates of Conformity to the requirements of technical regulations. It allowed the company to participate in open tenders with these products.

During the tenders to supply regulators for the Ukrtransgaz JSC, our new RTBK regulator was a worthy competitor among imported similar ones and not conceding by technical characteristics, it had a more attractive price.

In the shortest possible time, the first RTBK regulators of model В10.S of fully closed design with a shut-off valve in one body for the pressure of 10 MPa with a nominal diameter of 50 mm were manufactured.

The work on the project was carried out by:

Harkusha Oleksandr – Chief Designer of the plant

Kostenko Yevhen – Head of STI Department

Kuzmych Oleksandr – Deputy Director for production

Nerivnyi Andriy – Workshop Chief

Khomutov Yuriy – fitter of the minor assembly section

Ladnyk Serhiy – fitter of the mechanical assembly section

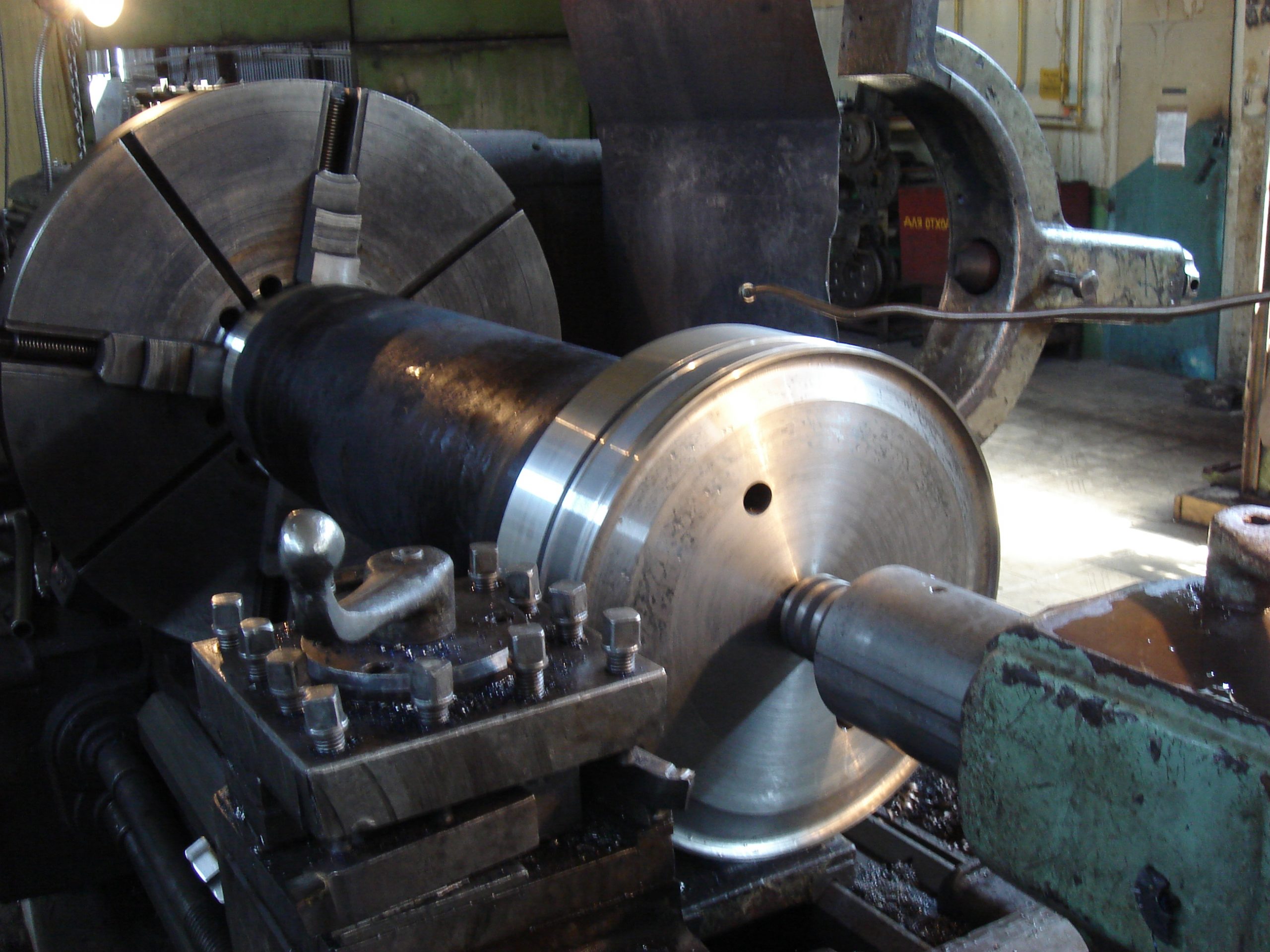

The entire staff of the plant was involved in the manufacturing of the regulators, including specialists of the turning section, milling section, the section of CNC machinery and auxiliary services.

The specialists of the Kontakt LLC plant had a challenging task to manufacture, test and ship a batch of new regulators within 60 days!