Specialists of the Kontakt LLC, Druzhkovsky gas equipment plant, designed a universal extruder, a press briquetting machine for waste.

Wood sawdust and other woodworking products, as well as husks of sunflower, buckwheat and rice, can be used as a raw material for the equipment.

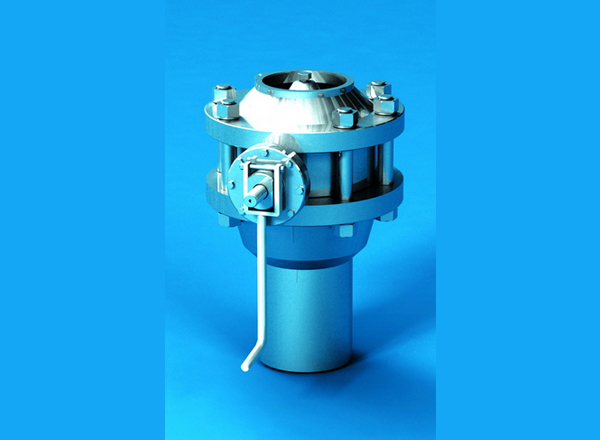

The screw press briquetting machine with an automated biomass feeder compacts waste by 6 to 12 times.

Installing an extruder will give you several advantages:

– You can use transport containers for waste transportation more efficiently.

– You can get additional profits from selling briquettes.

– Briquettes will help you in saving on fuel. They burn twice as slow as wood.

– The products of combustion of briquettes are eco-friendly, they do not contain sulfur and sulfur dioxide gas, and the carbon monoxide content is very low.

– The ashes from burning wood briquettes can be used as a potassium fertilizer.

The waste briquetting line includes a sleeve with fan and receiving hopper for raw material, screw presses, packaging machine, dryer and press cooling system. The equipment can be completed with a hammer mill.

Kontakt LLC is always open to cooperation