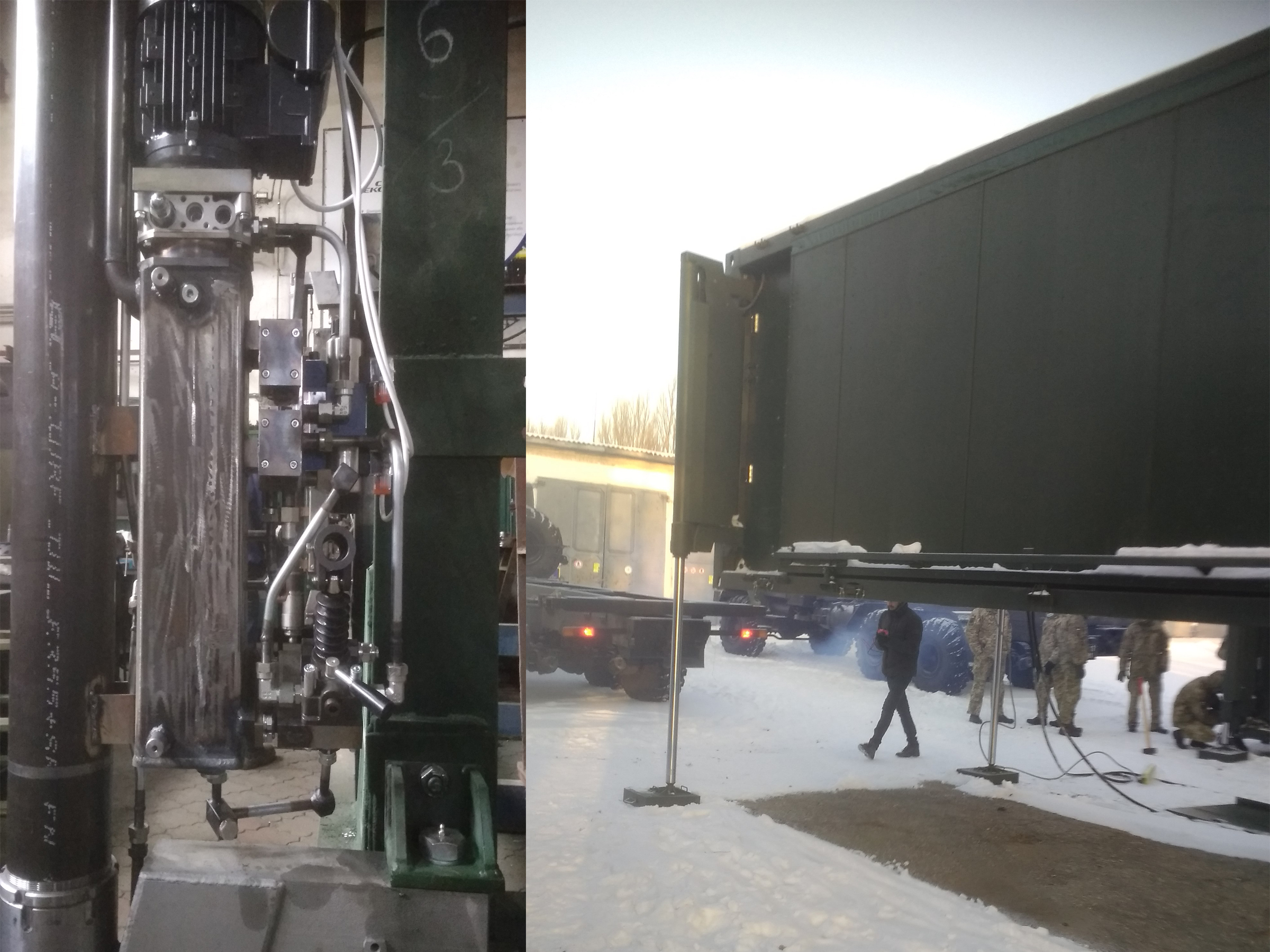

According to the customer’s technical assignment to solve a complex technological problem of transportation, loading and unloading of specialized modules (platforms), our company has developed and manufactured a set of hydraulic supports with the control system.

In the summer of 2019, the design and technological department of the Kontakt LLC plant began to study the problem according to its description and suggest solution options.

The developed hydraulic equipment makes it possible to lift a special module weighing 10 tons to a height of 1.7 meters onto a cargo platform for transportation. Then, unload it in the field conditions at slopes up to 7 degrees and wind gusts up to 20 meters per second.

In the fall of 2019, experimental equipment was manufactured and handed over to the Customer for testing.

Already on January 3, 2020, the plant shipped the first installation of the hydraulic loading and unloading device of the production sample.

In the first half of 2020, a new production line of the Kontakt LLC plant received a mass production order. Several sets of hydraulic control equipment were supplied.

The plant received a patent for its own development of a hydraulic loading and unloading device, go to the section

Improvement and modernization of our own developments is the daily work of our company’s engineers and feedback from the customer. Specialists take into account the results of the equipment operation and take into consideration the wishes for improvement.

Thus, the hydraulic loading and unloading device of the second generation of the 4M series has already been released.

The following characteristics have been improved: